Introduction

Introduction

In today’s fast-paced global supply chain, the cold chain industry is evolving faster than ever. More and more businesses are using temperature-controlled logistics to ensure their goods remain high-quality, do not spoil, and comply with standards.

From fresh produce and seafood to pharmaceuticals and vaccines, maintaining proper temperature is crucial. As demand for perishable goods grows, businesses that keep up with the latest cold storage trends gain a competitive edge. Innovations in technology, sustainability, automation, and delivery methods are transforming how products reach customers while keeping temperatures stable.

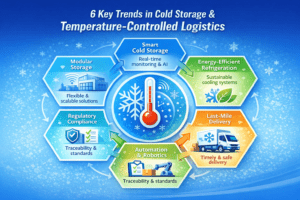

1. Smart Cold Storage Solutions

Cold storage facilities are no longer just large freezers. They are now smart, connected warehouses that use the Internet of Things (IoT), artificial intelligence (AI), and cloud-based monitoring tools to manage operations.

Benefits of smart cold storage include:

- Real-time monitoring: Sensors track temperature, humidity, and energy usage, triggering alerts when something goes wrong.

- Predictive maintenance: AI identifies potential equipment failures in advance, reducing downtime and repair costs.

- Improved inventory management: Automation helps monitor product shelf life, rotate stock, and minimize waste.

These technologies help businesses maintain compliance, ensure product quality, and optimize operational efficiency.

2. Energy-Efficient Refrigeration

Sustainability is a priority in modern logistics. Cold storage companies are adopting energy-efficient refrigeration technologies to cut costs and reduce environmental impact.

Key innovations include:

- Variable-speed compressors: Adjust cooling power based on actual demand.

- Eco-friendly refrigerants: Use alternatives that do not harm the ozone layer.

- Solar-powered systems: Hybrid setups combining solar energy with conventional refrigeration.

By implementing these solutions, businesses reduce emissions, save on operational costs, and comply with environmental standards.

3. Last-Mile Temperature-Controlled Delivery

The rise of e-commerce has made last-mile cold chain delivery a critical part of the supply chain. Maintaining the right temperature from warehouse to customer is essential for perishable goods.

Trends in last-mile delivery include:

- Electric refrigerated vans: Eco-friendly vehicles that maintain temperature during transit.

- IoT-enabled vehicles: Real-time tracking of location and temperature.

- Optimized delivery routes: Faster and safer delivery without compromising quality.

For industries like pharmaceuticals, vaccines, and fresh food, the last mile is often the most sensitive part of the supply chain, requiring innovative solutions.

4. Automation and Robotics

Automation is revolutionizing cold storage operations. More facilities are using robots and automated guided vehicles (AGVs) to pick, pack, and transport temperature-sensitive goods.

Benefits of automation:

- Reduces human errors in handling sensitive products

- Speeds up order fulfillment and improves efficiency

- Enhances safety for perishable or hazardous goods

Automation not only boosts productivity but also ensures consistent temperature integrity throughout the supply chain.

5. Regulatory Compliance and Traceability

Cold chain businesses operate under strict global regulations for food and pharmaceutical safety. Digital tools are increasingly used to ensure compliance.

Key solutions include:

- Blockchain tracking: Provides complete transparency and traceability from origin to delivery.

- Electronic logs and alerts: Monitor temperature and handling for audits.

- Rapid recall capabilities: Quickly identify and remove compromised products.

By leveraging technology, businesses reduce risk, maintain trust, and meet international standards.

6. Modular and On-Demand Cold Storage

Businesses need flexible solutions to adapt to seasonal demand or expansion Modular cold storage units allow companies to scale storage capacity without permanent infrastructure.

Advantages include:

- Quick expansion of storage capacity

- Ideal for seasonal or temporary products

- Lower upfront investment with greater operational flexibility

Modular solutions are increasingly adopted in e-commerce, pharmaceuticals, and food service, allowing businesses to meet changing supply chain needs efficiently.

Conclusion

The future of cold storage and temperature-controlled logistics is smart, sustainable, and highly automated. Companies that adopt trends like IoT monitoring, energy-efficient refrigeration, automation, last-mile solutions, and modular storage can ensure product quality, reduce waste, and stay competitive in a global supply chain that increasingly relies on perishable goods.

Investing in these innovations isn’t just about efficiency—it’s about delivering safety, reliability, and trust to customers, while preparing for the next generation of cold chain challenges.